An important choice for businesses operating in the constantly changing electronics sector is choosing a suitable PCB supplier. Numerous electronic products, including industrial machinery, medical equipment, smartphones, and laptops, are built on printed circuit boards (PCBs). Your PCBs' performance, dependability, and quality immediately affect the success and value of your final product.

This article covers the significant factors that business-to-business (B2B) experts should take into account when selecting a reliable PCB supplier.

PCBs are advanced devices with exact layouts and precise standards. By choosing a provider with a track record of quality and experience, you can be sure that the PCBs you receive will satisfy your unique needs. This is why picking the best PCB supplier is so important:

PCBs are advanced devices with exact layouts and precise standards. By choosing a provider with a track record of quality and experience, you can be sure that the PCBs you receive will satisfy your unique needs. This is why picking the best PCB supplier is so important:

The PCB sector is always changing due to the changing needs of customers and technology developments. The following are some of the significant trends that will influence PCB manufacturing heading forward:

The PCB sector is always changing due to the changing needs of customers and technology developments. The following are some of the significant trends that will influence PCB manufacturing heading forward:

Importance of Picking The Right PCB Supplier

PCBs are advanced devices with exact layouts and precise standards. By choosing a provider with a track record of quality and experience, you can be sure that the PCBs you receive will satisfy your unique needs. This is why picking the best PCB supplier is so important:

PCBs are advanced devices with exact layouts and precise standards. By choosing a provider with a track record of quality and experience, you can be sure that the PCBs you receive will satisfy your unique needs. This is why picking the best PCB supplier is so important:

- Reliability and Quality: Device problems, production delays, and even safety risks can result from substandard PCBs. Throughout the production process, a trustworthy supplier places a high priority on quality control, guaranteeing that your PCBs operate without any difficulties.

- Time to Market: It's critical to get your product onto the market as soon as possible in the highly competitive marketplace of today Your time-to-market plan may be greatly impacted by a supplier who uses effective production techniques and delivers things on schedule.

- Expense optimization: Although costs play a role, concentrating only on the most affordable option may not be the best choice of practice. A reputable supplier minimizes your overall costs by providing competitive prices and guaranteeing quality, and timely delivery.

- Adaptation & Innovation: A lot of business-to-business systems call for special PCB features or modern materials. Selecting a supplier with advanced abilities lets you experiment with creative product designs and features.

Emerging Trends in the PCB Industry

The PCB sector is always changing due to the changing needs of customers and technology developments. The following are some of the significant trends that will influence PCB manufacturing heading forward:

The PCB sector is always changing due to the changing needs of customers and technology developments. The following are some of the significant trends that will influence PCB manufacturing heading forward:

- Smaller PCBs: Printed circuit boards (PCBs) are becoming smaller due to the growing need for small, portable electronic gadgets.

- Flexible printed circuit boards (PCBs): Due to their ability to support curved or flexible form factors, FPCs are becoming more and more common in devices such as watches and medical applications.

- Higher Materials: To fulfill the demands of advanced programs, new materials with superior qualities are being created. These properties include high-temperature resistance, low-loss features, and increased signal integrity.

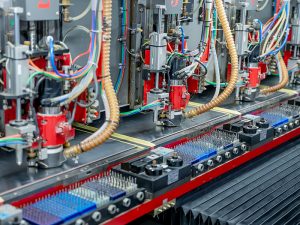

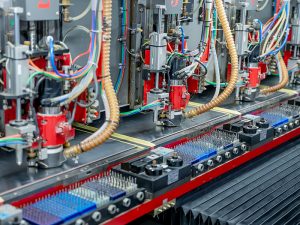

- Automating: To boost production capacity, lower mistake rates, and enhance manufacturing efficiency, automation and robotics are being used.

- 5G Technology: PCBs with the ability to handle higher frequencies and quicker data transmission rates are necessary for the arrival of 5G technology.

- 3D Printing: The quick prototyping of PCBs through 3D printing cuts down on development time and expenses. Are you determined to find the ideal PCB supplier for your company? Get in touch with us right now to talk about your particular requirements and get customized recommendations.