Electronic gadgets, such as smartphones allow seamless connection. They remain cool to the touch even if you use them for long hours. Manufacturers ensure the safety and highest performance standards by using FR4. It is a substrate with flame-resistant properties to keep your device safe. Let us talk more about the FR4 material specification used for PCBs.

FR4 is a substrate material that shows self-extinguishing when directly exposed to flame or heat. It is used for Printed Circuit Boards because of its heat-resistant and electrical-insulating properties. PCB manufacturers use this material for their reliability and durability. So, while purchasing the PCB, you should check the FR4 material specification.

FR4 is a substrate material that shows self-extinguishing when directly exposed to flame or heat. It is used for Printed Circuit Boards because of its heat-resistant and electrical-insulating properties. PCB manufacturers use this material for their reliability and durability. So, while purchasing the PCB, you should check the FR4 material specification.

What is Flame Retardant 4?

FR4 is a substrate material that shows self-extinguishing when directly exposed to flame or heat. It is used for Printed Circuit Boards because of its heat-resistant and electrical-insulating properties. PCB manufacturers use this material for their reliability and durability. So, while purchasing the PCB, you should check the FR4 material specification.

FR4 is a substrate material that shows self-extinguishing when directly exposed to flame or heat. It is used for Printed Circuit Boards because of its heat-resistant and electrical-insulating properties. PCB manufacturers use this material for their reliability and durability. So, while purchasing the PCB, you should check the FR4 material specification.

FR4 material specification- Mechanical and electrical properties

FR4 has good tensile strength, allowing the material to stay intact when stretched. The tensile strength of the material is up to 500 MPa, based on the composition and grade. It ensures the PCB endures stresses caused by the manufacturing process. Another significant factor is the flexural strength, which makes the material deformation-resistant. The maximum strength of the substrate material is about 600 MPa. So, while installing the FR4 PCB, there is no risk of flexing. FR4’s mechanical properties are related to temperature fluctuations. Higher temperature leads to reduced stiffness and strength. It may affect the PCB’s reliability and performance. While choosing the FR4 grade, engineers focus on the operating temperature of the particular application. PCB materials’ electrical properties also ensure impedance control and signal integrity. In the case of the FR4 material, the most significant aspects are-- Dielectric constant- Depending on the composition and grade, FR4’s dielectric constant is up to 4.8.

- Dissipation factor- It measures the material's tendency to disperse electrical energy.

- Signal integrity- FR4 ensures minimal electrical energy is dissipated as heat.

How is Flame Retardant 4 applied for PCB?

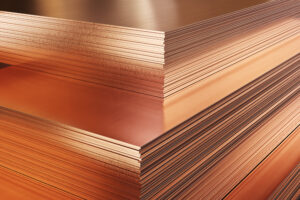

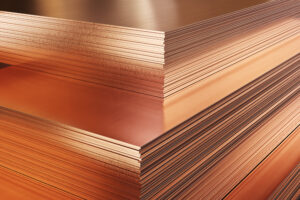

FR4 has some special properties, which make it perfect as a substrate for PCB manufacturing. When used properly, such properties create the base for PCBs. FR4 is the primary material to design the boards. The laminated FR4 board has multiple copper foil layers. The copper develops high-quality circuits in the product and covers different sides, depending on the board’s design.Does the FR4 material have limitations?

FR4 has a few limitations that you must know about using it for your project.

- FR-4 boards are the best insulators, although excessive stress may damage them.

- Frequency causes a variation in the FR4's dielectric constant. It prevents the FR4 boards from achieving controlled impedance.

- FR4 circuit boards cannot endure extreme temperatures, and this limitation may cause damage.

- Signal loss is another important factor for the PCB design. FR4 is not the right choice for high-frequency applications because of the higher dissipation factor.