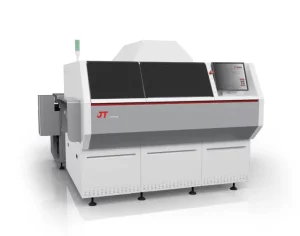

In the dynamic landscape of manufacturing, technological advancements continue to shape the way industries operate. One such innovation that's making waves is the auto-insertion machines. This cutting-edge equipment is redefining the efficiency and precision of electronic component insertion in circuit boards. In this article, we delve into the world of auto-insertion machines, exploring their functionalities, benefits, and their role in the success story of companies like JT.

Auto-insertion machines are automated systems designed to place electronic components onto printed circuit boards (PCBs) with remarkable precision and speed. These machines eliminate the need for manual assembly, reducing errors and increasing production rates. From resistors and capacitors to diodes and connectors, these machines handle a wide array of components, ensuring accurate placement in designated locations.

Auto-insertion machines are automated systems designed to place electronic components onto printed circuit boards (PCBs) with remarkable precision and speed. These machines eliminate the need for manual assembly, reducing errors and increasing production rates. From resistors and capacitors to diodes and connectors, these machines handle a wide array of components, ensuring accurate placement in designated locations.

Understanding Auto-Insertion Machines

Auto-insertion machines are automated systems designed to place electronic components onto printed circuit boards (PCBs) with remarkable precision and speed. These machines eliminate the need for manual assembly, reducing errors and increasing production rates. From resistors and capacitors to diodes and connectors, these machines handle a wide array of components, ensuring accurate placement in designated locations.

Auto-insertion machines are automated systems designed to place electronic components onto printed circuit boards (PCBs) with remarkable precision and speed. These machines eliminate the need for manual assembly, reducing errors and increasing production rates. From resistors and capacitors to diodes and connectors, these machines handle a wide array of components, ensuring accurate placement in designated locations.

The Advantages of Auto-Insertion Machines

- Unparalleled Precision: Auto-insertion machinesexcel in placing components with micrometer-level accuracy. This precision minimizes the chances of faulty connections, enhancing the overall reliability of electronic devices.

- Increased Efficiency: Traditional manual insertion is a time-consuming process prone to human errors. Auto-insertion machines streamline the assembly line, boosting productivity and reducing production timelines significantly.

- Versatility: These machines are versatile, accommodating various component sizes and shapes. This flexibility is crucial in the ever-evolving landscape of electronics.

- Cost-Effective: While the initial investment might be substantial, the long-term cost savings are substantial. Fewer errors mean reduced material wastage and less rework, contributing to better resource utilization.