There are many abrasive clothes you can find for sale, but when buying, you must always be careful as to what is available in the market. I would like to inform you that you read about our best abrasive clothes and would wish to buy them to avoid any scam.

2. Silicon carbide powder will be mixed with a resin binder to form a paste that can be coated onto a woven fabric backing or used as an adhesive. Silicon carbide adds strength, hardness, durability, and thermal shock resistance to the coating; it also enhances abrasion resistance and improves the life of finished products such as cutting tools.

Ceramic grain belts have several advantages over other types of abrasives:

They don't leave a waxy finish like paper abrasives do, which means they won't attract dust as much.

They don't wear out as rapidly as some other abrasives.

The aluminum oxide grains are very hard and can withstand heavy pressure without breaking down under stress. This makes it a good choice for heavy-duty sanding jobs on tough materials like hardwoods, plastics, etc. These belts can be used wet or dry, depending on your needs and requirements.

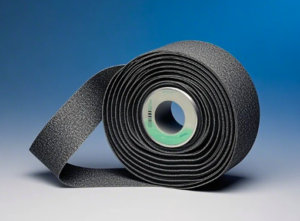

Abrasive Cloth: Silicon carbide grain sanding belt WYC369

This silicon carbide grain belt is a high-quality abrasive belt with excellent anti-wear and abrasion resistance features. The excellent performance of this silicon carbide grain belt enables it to be used for a long time in the production of metal parts, precision machine parts, automobile components, the electronics industry, the chemical industry, and other industrial fields.Features:

1. High hardness and strength; good wear resistance; no cracking; no rusting; low thermal expansion coefficient and high thermal conductivity chemical properties that are stable in the presence of high-temperature oxidization and low-temperature dehydration, for example;2. Silicon carbide powder will be mixed with a resin binder to form a paste that can be coated onto a woven fabric backing or used as an adhesive. Silicon carbide adds strength, hardness, durability, and thermal shock resistance to the coating; it also enhances abrasion resistance and improves the life of finished products such as cutting tools.

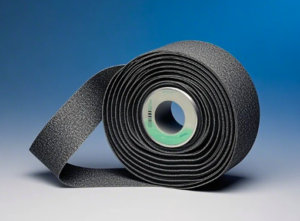

Abrasive Cloth: Ceramic grain sanding belt

Ceramic grain sanding belts are designed to remove material from a surface. They are primarily used in woodworking and metalworking but can be used on many different materials. Ceramic grain belts can supply better finishes than other belts, but they will wear out faster. Ceramic grain belts are made of crushed ceramic particles embedded in a resin binder that is then pressed into a belt shape. This makes the belt more supple than glass-bonded abrasives, which makes them easier to use on curved surfaces.Ceramic grain belts have several advantages over other types of abrasives:

They don't leave a waxy finish like paper abrasives do, which means they won't attract dust as much.

They don't wear out as rapidly as some other abrasives.

Abrasive Cloth: Aluminum oxide grain sanding belt WX167

Aluminum oxide grain sanding belt WX167 is a lovely choice of abrasive belt. It is made up of aluminum oxide grains with a rubber backing. These belts are used for all kinds of woodworking, metal, or plastic finishing applications where a high-quality finish and durability are required. The main feature of this belt is its ability to cut through any material with ease.The aluminum oxide grains are very hard and can withstand heavy pressure without breaking down under stress. This makes it a good choice for heavy-duty sanding jobs on tough materials like hardwoods, plastics, etc. These belts can be used wet or dry, depending on your needs and requirements.