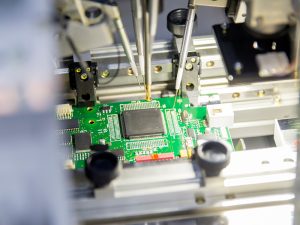

Modern electronics require PCB assembly (Printed Circuit Board assembly) to function and be connected. As demand for high-quality electronic devices increases, efficient PCB assembly becomes crucial to ensure product performance. In this industry, China has become a global leader by providing dependable and reasonably priced assembly services. In this article, we’ll explore the advantages of choosing PCB assembly China, while acknowledging some challenges businesses face.

China has gained a reputation for PCB assembly that goes beyond cost-effectiveness in recent years. To guarantee that their goods fulfill international standards, a large number of Chinese firms have implemented stringent quality control procedures and obtained foreign certifications like ISO9001 and UL. As a result, dependable, long-lasting PCB assemblies that can satisfy the demands of numerous industries have been produced.

Innovation plays a significant role in the PCB assembly industry in China. With the integration of Artificial Intelligence (AI) and Internet of Things (IoT) technologies, Chinese manufacturers are increasing production efficiency and adapting to rapidly changing industry demands. Because of this, PCB assembly in China is a progressive and active link in the electronics supply chain.

China has gained a reputation for PCB assembly that goes beyond cost-effectiveness in recent years. To guarantee that their goods fulfill international standards, a large number of Chinese firms have implemented stringent quality control procedures and obtained foreign certifications like ISO9001 and UL. As a result, dependable, long-lasting PCB assemblies that can satisfy the demands of numerous industries have been produced.

Innovation plays a significant role in the PCB assembly industry in China. With the integration of Artificial Intelligence (AI) and Internet of Things (IoT) technologies, Chinese manufacturers are increasing production efficiency and adapting to rapidly changing industry demands. Because of this, PCB assembly in China is a progressive and active link in the electronics supply chain.

Despite the clear advantages, there are challenges when working with PCB assembly in China. Companies that deal with proprietary designs and technologies continue to be concerned about protecting their intellectual property (IP). It’s essential to partner with trusted manufacturers that have proven safeguards in place.

Trade tariffs and geopolitical concerns can also affect how much it costs and how simple it is to conduct business in China. To minimize interruptions, companies should be informed about anticipated changes in trade legislation and make appropriate plans accordingly.

Despite the clear advantages, there are challenges when working with PCB assembly in China. Companies that deal with proprietary designs and technologies continue to be concerned about protecting their intellectual property (IP). It’s essential to partner with trusted manufacturers that have proven safeguards in place.

Trade tariffs and geopolitical concerns can also affect how much it costs and how simple it is to conduct business in China. To minimize interruptions, companies should be informed about anticipated changes in trade legislation and make appropriate plans accordingly.

Why China for PCB Assembly?

China has made significant investments in skilled labor and manufacturing facilities, contributing to its domination in the PCB assembly business. PCB assembly in China has become known for providing cost efficiency without compromising on quality, making it an attractive option for both startups and major corporations. Advanced technology, such as automated production lines, is utilized by Chinese manufacturers to increase the speed and accuracy of assembly procedures. This guarantees consistency in mass manufacturing and shortens turnaround times. Businesses in the consumer electronics, automotive, and telecommunications sectors frequently choose Chinese manufacturers when looking for scalable and effective assembly.Cost-Efficiency and Scale

The cost structure of PCB assembly in China is one of its biggest attractions. Chinese producers can provide competitive pricing for large orders because they enjoy economies of scale. This greatly benefits companies trying to cut expenses without sacrificing quality. Labor costs in China remain competitive compared to other regions, like the United States and Europe, despite recent increases. Furthermore, Chinese businesses frequently maintain tight ties with regional suppliers, which lowers production costs overall.Innovation and Quality Control

China has gained a reputation for PCB assembly that goes beyond cost-effectiveness in recent years. To guarantee that their goods fulfill international standards, a large number of Chinese firms have implemented stringent quality control procedures and obtained foreign certifications like ISO9001 and UL. As a result, dependable, long-lasting PCB assemblies that can satisfy the demands of numerous industries have been produced.

Innovation plays a significant role in the PCB assembly industry in China. With the integration of Artificial Intelligence (AI) and Internet of Things (IoT) technologies, Chinese manufacturers are increasing production efficiency and adapting to rapidly changing industry demands. Because of this, PCB assembly in China is a progressive and active link in the electronics supply chain.

China has gained a reputation for PCB assembly that goes beyond cost-effectiveness in recent years. To guarantee that their goods fulfill international standards, a large number of Chinese firms have implemented stringent quality control procedures and obtained foreign certifications like ISO9001 and UL. As a result, dependable, long-lasting PCB assemblies that can satisfy the demands of numerous industries have been produced.

Innovation plays a significant role in the PCB assembly industry in China. With the integration of Artificial Intelligence (AI) and Internet of Things (IoT) technologies, Chinese manufacturers are increasing production efficiency and adapting to rapidly changing industry demands. Because of this, PCB assembly in China is a progressive and active link in the electronics supply chain.

China's PCB Assembly Challenges

Despite the clear advantages, there are challenges when working with PCB assembly in China. Companies that deal with proprietary designs and technologies continue to be concerned about protecting their intellectual property (IP). It’s essential to partner with trusted manufacturers that have proven safeguards in place.

Trade tariffs and geopolitical concerns can also affect how much it costs and how simple it is to conduct business in China. To minimize interruptions, companies should be informed about anticipated changes in trade legislation and make appropriate plans accordingly.

Despite the clear advantages, there are challenges when working with PCB assembly in China. Companies that deal with proprietary designs and technologies continue to be concerned about protecting their intellectual property (IP). It’s essential to partner with trusted manufacturers that have proven safeguards in place.

Trade tariffs and geopolitical concerns can also affect how much it costs and how simple it is to conduct business in China. To minimize interruptions, companies should be informed about anticipated changes in trade legislation and make appropriate plans accordingly.